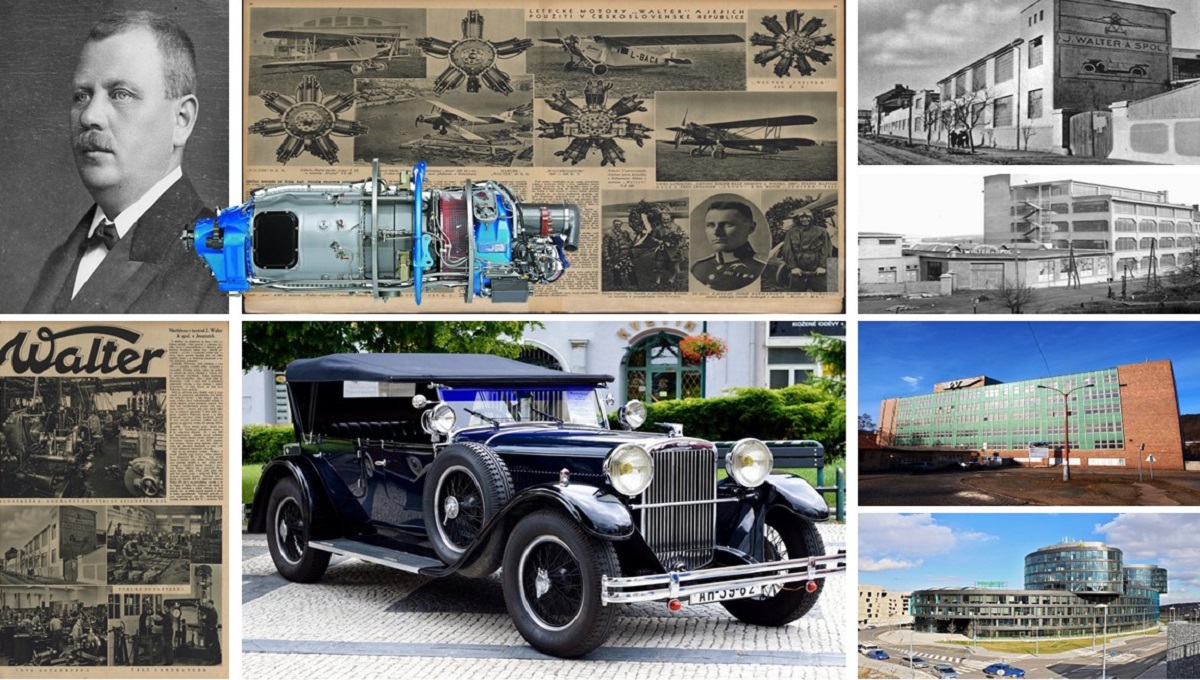

Crafting today’s blog post has been an immersive journey, requiring hours of devoted research and delving into so many of my favorite subjects. Get ready to unravel an enthralling array of historical revelations, ones that are likely to be new and enlightening to you, all centered around the captivating legacy of Josef Walter. From the early days of bicycles to the revving engines of motorcycles, and from there, soaring to the zenith of automobiles and the skies of aviation, we’re about to uncover the multifaceted accomplishments of an exceptional individual.

Josef Walter, a visionary artisan, left an indelible mark in history with what could be aptly dubbed the “Rolls Royce” of Czech automobiles. Yet, his influence extends far beyond this zenith, encompassing the very engines that propelled iconic Soviet MIG fighter planes and GE turboprop engines. Such an extraordinary range of achievements is a testament to his far-reaching genius and pioneering spirit.

And that’s just the beginning. As we traverse the corridors of time, vintage magazine clippings act as our windows to an era long past. Through these fragments from the past, we’re not merely shown striking automobiles; we’re also granted a unique insight into the exhilarating world of flight. We hear the story of a military pilot from the late 1920s, offering us precious glimpses into the soaring passion that propelled skyward ambitions.

From Humble Beginnings to the Rebirth of Waltrovka: The Legacy of Josef Walter

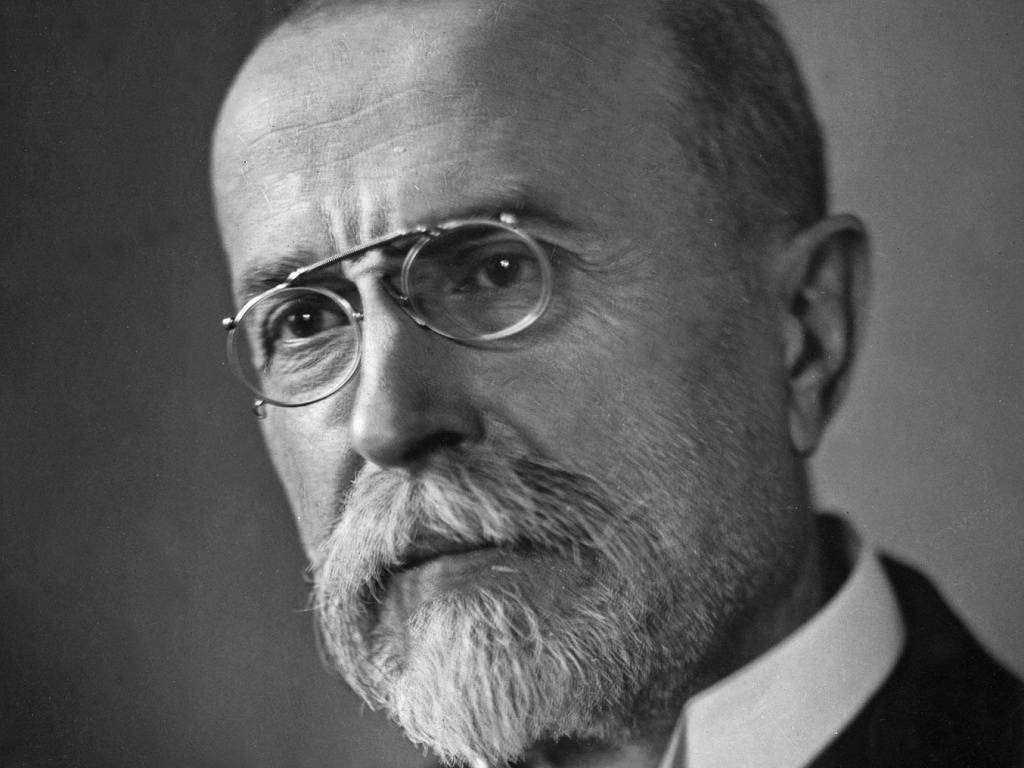

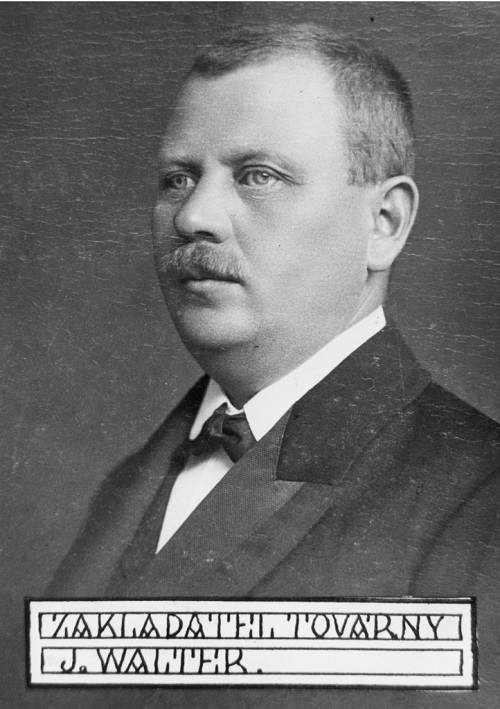

The journey of Josef Walter (1873–1950) began with a simple machine fitter’s apprenticeship certificate, a foundation that would lay the groundwork for a remarkable story of ingenuity and progress. As he embarked on his career, he transitioned from mending bicycles at a modest workshop on Kořenského Street in Smíchov (number 753/XVI), to envisioning and crafting his own line of motorcycles. The year was 1903 when the first Walter motorcycles graced the roads of Europe, a testament to Josef Walter’s unwavering determination.

Josef Walter founded Walter Engines in 1898 in Prague.

Six years down the road, in a pivotal moment of innovation, the world witnessed the emergence of the Walter 4-seat motor tricycle. This marked the initial stride towards the creation of an automobile bearing the iconic winged-W emblem on its front. By 1913, as the company’s influence burgeoned, the search for suitable land to erect a factory led them to Jinonice. With diligence and perseverance, they secured the necessary property and laid the foundation for their future endeavors.

A decade onwards, the factory embraced a pivotal shift that would define its trajectory for decades to come. The production lines hummed to life, crafting aircraft engines that would become the hallmark of the company. The post-World War II era witnessed the factory’s transformation into a monumental industrial powerhouse, recognized as Motorlet. Its growth was a testament to resilience and innovation, and it became one of Central Europe’s largest manufacturing facilities.

But as history often takes unexpected turns, the final chapter of this remarkable tale concluded in 2008. Yet, like a phoenix rising from the ashes, the spirit of innovation, community, and progress was reignited. The phoenix of history’s Motorlet was reborn as the modern marvel we know today – Waltrovka.

Waltrovka encapsulates not only the legacy of Josef Walter’s pioneering spirit but also the evolution of an entire community. From repairing bicycles to crafting engines for the skies, from a modest factory to an industrial titan, the journey of Josef Walter and the rise of Waltrovka is a story of unwavering dedication, visionary leadership, and the enduring pursuit of progress.

More Detailed History

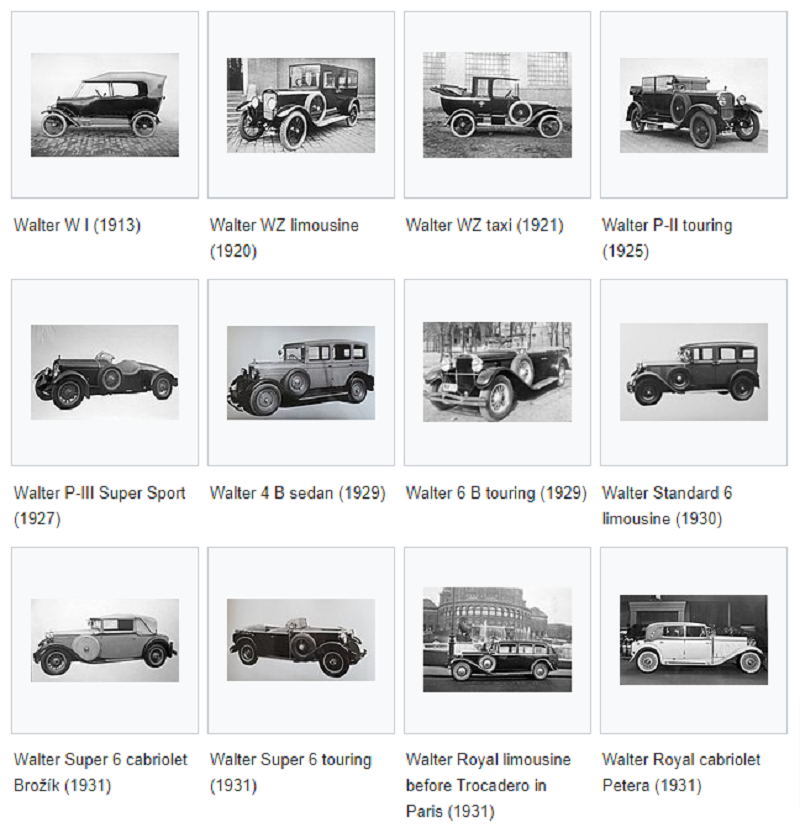

In the year 1913, as the company’s success continued to burgeon, it took a significant leap by relocating from its factory on Na Zatlance Street (number 1120/XVI) to a state-of-the-art new facility in Jinonice. This marked a pivotal moment, as the company embarked on the production of automobiles designed entirely in-house. The inaugural creation, the four-seater W 1, featured a four-cylinder, water-cooled engine and showcased its prowess by triumphing in the Zbraslav – Jíloviště race while still in prototype form.

However, the company’s trajectory was momentarily redirected due to the exigencies of wartime production. With the establishment of the Republic, it shifted its focus back to automobiles, crafting notable models such as PI, P-II, P-III, and P-IV.

Between 1919 and 1937, the Akciová Factory of Automobiles, J. Walter and spol. Prague-Jinonice, proudly manufactured approximately 5,500 cars and trucks.

After the First World War, Walter cars were even considered the Czech Rolls-Royce for their luxury and reliability.

Walter Super 6 touring (1930).

Absolutely gorgeous – wouldn’t you agree?

Where are the days when a young man in a bicycle shop could dream of building such lovely cars…

Walter Royal cabriolet (1931).

A noteworthy juncture arrived in 1931 when the company secured a licensing agreement with Fiat. Subsequently, it embarked on the production of renowned Fiat models, most notably the Fiat 514 and Fiat 508 Ballila, which bore the distinct Walter-Bijou and Walter-Junior badges.

Walter Junior SS roadster – Fiat 508 Balilla Spider Sport (1935).

This marked a synergistic collaboration that spanned the following years and solidified the company’s standing in the realm of automobile craftsmanship.

Image: Jana Králíka Zmizelá Praha: Automobily a motocykly.

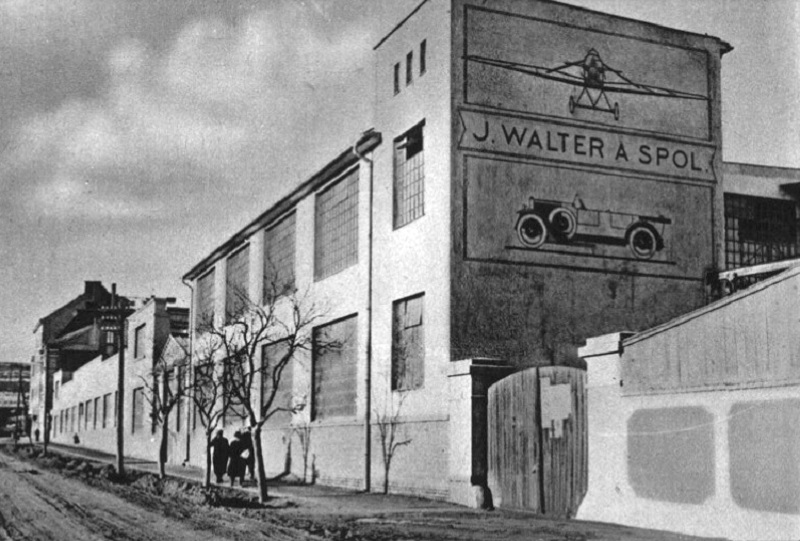

Waltrovka, situated in Prague’s Jinonice district, once housed the Josef Walter and Co. factory. Following nationalization, it became known as Motorlet sp and later as Walter Engines. In 2008, after being sold, it adopted the new name GE Aviation Czech, serving as the aviation production division of General Electric.

Founded by Josef Walter in 1911, the company initially operated under the name Josef Walter and spol. Later, in 1919, it was renamed Josef Walter a spol. Subsequently, in January 1932, the company underwent another name change to become the “Walter Stock Company, Automobile and Aircraft Engine Factory.” After World War II, the nationalized company was referred to as Letecké závody np and was later known as Motorlet np from 1949.

In 1913, the production of Walter WI cars was initiated. From 1920 to 1930, the company manufactured various car models, including the Walter PI with a power of 27 kW, the Walter P-II with a power of 34 kW, the Walter P-III with a power of 40 kW, and the Walter P-IV with a power of 47 kW. In 1928, the production of Walter 4-B (47 kW) and Walter 6-B (80 kW) cars commenced. These car models garnered success, leading to the development of other variants such as Walter Standard (80 kW), Walter Super (94 kW), Walter Regent (94 kW), and Walter Royal. Additionally, the factory produced Fiat 508 and Fiat 514 cars under license. The automotive production continued until 1951, marking the end of an era as the final Aero Minor car rolled off the production line. After four decades of operation, the factory ceased its involvement in the automotive industry.

Exploring the Legacy of Walter Engines: A Pioneer in Czech Engine-Building

When it comes to the realm of aeronautics and engine craftsmanship, few names resonate as profoundly as Walter Engines. Rooted in Czech engineering excellence, Walter Engines has left an indelible mark on the industry, particularly renowned for its exceptional turboprop engines. Let’s delve into the captivating history of this illustrious company that has been soaring through the skies for over 100 years…

A Humble Beginning: From Motorcycles to Engines

From bicycles and tricycles, Walter expanded into the automobile business. In 1923, two decades after the Wright brothers’ first powered flight, the company moved into the quickly growing aviation industry.

Originally, the company specialized in the production of motorcycles and motor tricycles, showcasing their mechanical prowess. However, their innovative spirit quickly led them to explore other avenues, and between 1913 and 1954, they ventured into the realm of automobiles. The company showcased their adaptability by producing vehicles of their own design, as well as under Italian license, including notable models like Fiat 508 Balilla, Fiat 514, Fiat 522, and Fiat 524.

Taking Flight: Aeronautical Ventures

On May 22, 1906, Orville and Wilbur Wright received a patent for “new and useful improvements to the flying machine.” Czech engineers weren’t far behind them.

On April 16, 1910, Jan Kašpar became the first Czech pilot. He designed his own plane and engine and later flew in a Bleriot XI. The flight covered two kilometres at a height 20–25 metres. This day became a celebrated milestone in Czech aviation because of the flight and Kašpar being the first pilot of Czech nationality.

The early 1920s marked a significant turning point for Walter Engines as they ventured into aeronautics. They began producing BMW aircraft engines under license, but it didn’t take long for their ingenuity to shine. In 1923, they unveiled their first aircraft engine, the NZ 60, a radial 5-cylinder engine fitted onto the Avia BH-5 aircraft. As time progressed, Walter Engines diversified their offerings, manufacturing engines such as Bristol Jupiter, Mercury, and Pegasus under license during the 1930s.

Walter’s design duo Novak-Zeithammer built the NZ-60 engine that started it all. This example is in the collection of the Aviation Museum in Prague.

Their commitment to innovation was evident in the development of their original designs, including inverted inline 4 and 6-cylinder engines, and a remarkable inverted V 12-cylinder engine in 1936.

Navigating Turbulent Times: World War II and Beyond

World War II posed challenges, but Walter Engines persevered. They played a crucial role by producing Argus engines during the war years. The aftermath of the war saw changes in ownership and the company was nationalized in 1946, eventually renamed as Motorlet. In the years that followed, they embraced new ventures, including the production of Soviet piston engines under license. Notably, they played a pivotal role in the production of the Klimov VK-1 reactor, a groundbreaking endeavor that found its place on the iconic MiG-15 aircraft.

In 1952, Walter produced the jet engine for Soviet MiG-15 fighter jets.

The Evolution Continues: Turboprop Triumph

By 1967, Walter Engines was poised to reshape the landscape of aeronautics once again. Their meticulous engineering efforts resulted in the creation of the M601 turboprop engine. Tailored for business aircraft, agricultural planes, and military training and liaison aircraft, the M601 soon found its place on the formidable Let L-410 aircraft.

Privatization and Innovation

In 1995, the company took a new direction as it underwent privatization, reverting to the name Walter. Subsequently, in 2005, the aircraft department underwent a rebranding, becoming Walter Engines. These changes set the stage for a series of strategic moves that would redefine the company’s trajectory.

A New Chapter: Mergers and Acquisitions

In a bold move, the Czech investment group FF Invest acquired Walter Engines in July 2006. Following this, in March 2007, Walter Engines joined forces with Avia, as well as the precision machining company CPS, culminating in a merger that promised unparalleled synergies.

A Global Endeavor: GE Aviation’s Involvement

The year 2007 saw another significant milestone as GE Aviation entered the picture. In September 2007, GE Aviation acquired Walter Engines, a strategic maneuver that allowed them to position themselves as key players in the low-power turboprop market. By July 2008, this acquisition was successfully completed, enabling GE Aviation to present the M601 turboprop as a formidable alternative to the established PT6 engine. Aiming high, the objective was set to escalate M601 production from 120 to an astonishing 1000 units per year by 2012.

A Timeless Legacy

The history of Walter Engines is a testament to the power of innovation and resilience. From their humble beginnings in motorcycles and automobiles to their groundbreaking contributions to aeronautics and turbine technology, the company’s journey has been nothing short of remarkable. As their legacy continues to soar through the skies, it’s evident that Walter Engines’ influence on the world of engines and aviation will endure for generations to come.

Did you know that GE’s Turboprop Business Was Born in a Czech Bike Shop?

Exploring Rezidence Waltrovka: A Blend of History and Modernity in Prague

Nestled in the heart of Prague 5 – Jinonice, right by the bustling Radlická Radial Road, stands the impressive complex of residential and office-administrative buildings known as Rezidence Waltrovka. The name “Waltrovka” draws its essence from the former Walter Engines factory, once dedicated to producing automobiles and aircraft engines, whose grounds now host this contemporary residential haven.

The Waltrovka project revitalized a sizable part of Jinonice in Prague where the former Walter Motors factory used to be. The site has seen offices, shops, and a 2-hectare park all spring up there over the recent years. The project’s main goal was to create a new, modern city district and offer its visitors everything they need, all right next to metro line B.

Unveiling the Project

The crowning jewel of this development is the Aviatica building. The journey of constructing this architectural marvel commenced in March 2016, with the construction of residential buildings on the northern side of Walter Square. Notably, the modified logo of Walter Engines now graces the identity of this novel building complex. Backed by the visionary Penta Investments group, the project reached its completion by the close of 2020.

The layout of the complex is intriguingly reminiscent of a lizard or crocodile, characterized by two main sections:

- Residential Area: Comprising rows of family homes and multi-story residential buildings.

- Office-Administrative Area: Further divided into three buildings:

- Aviatica (No. 921): Located between Kačírkova Street and U Trezorky, this was the pioneering structure completed in 2015. It sets the tone for the entire residence.

- Mechanica (No. 329): Situated on the southern and western sides of Walter Square, this building is an amalgamation of three smaller sections. One of these sections is a newly constructed space, while another is the preserved Walter Engine building. Notably, this area will house a novel healthcare facility, including a clinic by the EUC group and a physiotherapy center led by Prof. Pavel Kolář, specializing in Movement Medicine. This clinic, an extension of CMC (Canadian Medical Care), aims to offer exceptional care in the fields of surgery, orthopedics, gynecology, ENT, and stomato-surgery. The facility boasts not only consultation rooms but also fully-equipped operation theaters.

- Dynamica (No. 982): Positioned between Radlická Street and Kačírkova Street, on the eastern side of the Aviatica building.

Celebrating Milestones

On October 18, 2017, a grand celebration marked the inauguration of the new Walter Square. This new landmark encompassed a newly built footbridge connecting to the Jinonice metro station, the three-part Mechanica building, and the captivating Pegasus sculpture by renowned artist David Černý.

The footbridge was crafted by the Technical Administration of Roads for the city of Prague, a project spearheaded by Penta. Additionally, the administration constructed a reroute for Na Hutmance Street, introduced new circular intersections, sidewalks, and bus bays. An investment of 270 million Czech Korunas transformed these ideas into tangible infrastructure.

In the heart of Prague 5, Rezidence Waltrovka stands as a testament to the fusion of historical significance and contemporary design. With its unique layout, diverse offerings, and a nod to the industrial past, it offers residents and businesses alike a distinctive place to call home.

The project has made revitalizing a vast chunk of land in Praha’s Jinonice district where the factory used to stand its goal. In its place, new office and residential blocks as well as shops are being built, combining today’s world of functionality, efficiency, and services with greenery, comfort, and relaxation. The site’s original character has been kept along with several of the historical buildings and the road.

The modified Walter Engines logo is also the logo of the new building complex.

Fascinated by old cars and airplanes and their manufacture, I found these few pages and decided to translate the information. I hope you enjoy today’s post.

The Jinonice Waltrovka was established in 1896 and initially produced only motorcycles and automobiles. The beginnings were not grand, but the company was founded on solid foundations, and all components worked purposefully. The endeavor to always achieve the best that could be attained at that time led primarily to the requirement of refining production. It can now be happily noted that the path taken by the development of Waltrovka was correct.

After the revolution, as we sought avenues to gain independence from foreign industries, the curiosity was palpable among those who closely followed aviation and grasped its significance. Everyone wondered which Czechoslovak enterprise would dare to embark on the production of aircraft engines. This was a pivotal time, fraught with risk, as our reliance on foreign industry for aviation was total. During this period, the prowess of Waltrovka came to the forefront. It saw introducing aircraft engine production as not just a duty but a matter of national pride. Guided by a commitment to precision manufacturing, progress surged rapidly. The maiden aircraft engine of their own making was a five-cylinder radial engine boasting 60 horsepower, and air-cooled for efficiency. As early as 1923, it secured homologation as the very first domestically-produced, air-cooled engine. It swiftly garnered the favor of the aviation community. In 1924, the Walter factory proudly recorded the initial triumphs of their creation in national competitions, with a series of national records serving as a testament to their achievement.

Soon after, the Walter factory ventured into the production of a large-type engine, water-cooled, with a performance range of 185 to 240 horsepower. This engine quickly gained widespread popularity. Encouraged by these achievements, our skilled pilots dared to undertake long-distance flights in domestically-produced aircraft powered by Walter engines. They journeyed to the capitals of various countries, showcasing the capabilities of Czech-made airplanes. In the same year, Czech workmanship in Walter engines faced even more stringent tests. The Avia factory introduced its BH 11 aircraft, equipped with the Walter NZ 60 engine, to the international Coppa d Ilalia race. For an industry still young, this was undeniably a bold move, driven by the conviction that everything necessary for success had been done, justifying this step. The outcome affirmed that they hadn’t overestimated their capabilities. The Czechoslovak product, the Avia BH 11 airplane with the Walter NZ 60 engine, earned its laurels under the guidance of Chief Pilot Fritsche, winning first prizes.

This swiftly propelled the Czechoslovak product to the forefront of the international market, offering undeniable evidence of the genuine significance of the Walter factory. Just a year later, this was further solidified by the definitive acquisition of the “Coppa S Italia” award and a fresh victory in the economical aircraft race at Orly in France. In the subsequent evolution, Walter engines, whose series continues to expand, consistently garnered attention with world records and remarkable long-distance flights each year, the latest of which remain unchallenged. Today, the products of the Walter factory hold a global reputation. Across almost all European countries, in America, China, and beyond, aircraft of diverse designs and origins utilize Walter engines. The fact that many foreign aircraft manufacturers request Walter engines for their new aircraft models, intended for upcoming international competitions, serves as the best testament to the esteem Walter engines hold on the vast global market.

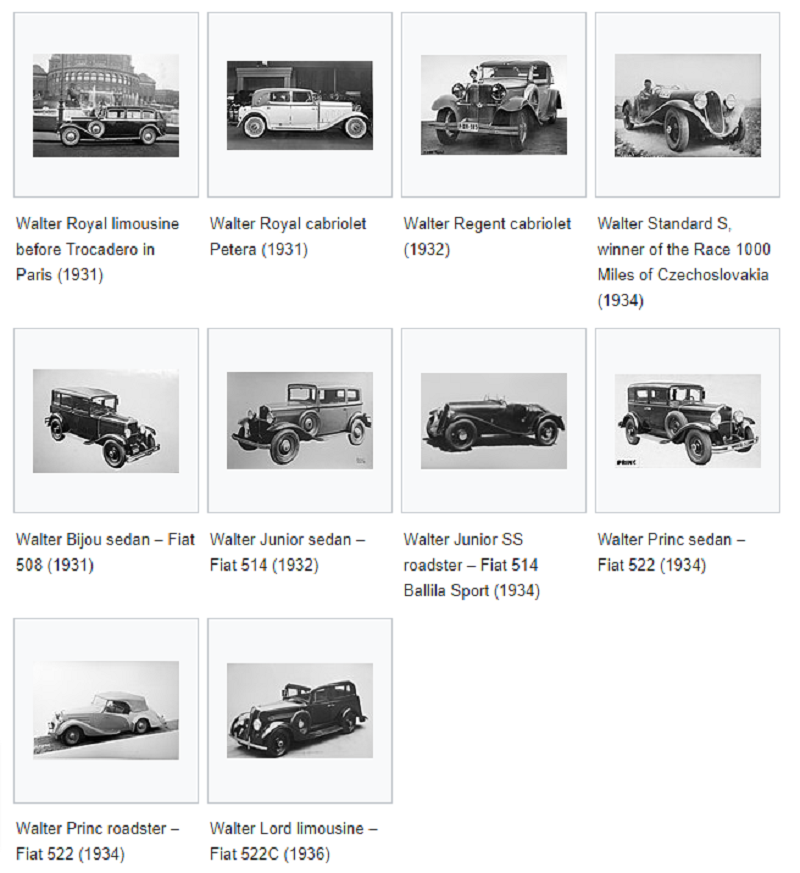

The factory premises of J. Walter & Co. in Prague-Jinonice consist of a series of large, well-lit buildings. These buildings, suited to the nature of the work conducted within, are single-story with overhead lighting or multi-story constructions. Components for automobiles and aircraft engines are machined in shared workshops, eliminating division in production. Consequently, the factory employs a specialized workforce for aircraft engine production, appropriately trained and perfected within the factory. While this circumstance might slightly raise production costs, it yields the result that not only aircraft engines but also automobiles are manufactured with extraordinary precision, enhancing their durability to a remarkable degree. The first workshop, known as the “Old Workshop,” differs from the newer ones solely in its continued use of transmission drive. Nonetheless, the transmission drive remains in use as a testament to earlier equipment, and it is retained only because it continues to be effective. Just like in the “new lathe” workshop, here too, the latest machining machines of domestic and foreign origin are employed. In the “new lathe” workshop, individual machines are powered by separate electric motors.

During production, each component undergoes quality checks by the inspection department as many times as there are different operations performed on that specific component. This ensures that the delivered components for assembly are flawless and uniform. As the severity of control cannot be compromised, automobile components are inspected with the same rigor as aircraft engine parts, once again reinforcing the quality of the Walter automobile.

The factory possesses its own large, modern foundry that supplies the workshops with aluminum, cast iron, and bronze castings. Special proprietary alloys of various metals are also assembled here, combining lightweight with desired strength.

As a modern enterprise, the factory also has laboratories where both its own castings and bar material, as well as various forgings, undergo rigorous and precise testing. Unlike the manufacturing process, the work in the technical office is divided into divisions for automobiles and aircraft engines. Both divisions employ a considerable number of experienced engineers, most of whom have gained expertise through foreign practical experience.

Components that have been completed and deemed flawless through thorough inspection are transported to the assembly departments, where they are used to assemble automobiles or aircraft engines. The assembly departments of the “Walter” company are notable for their brightness and spaciousness, enabling precise and calm work.

The assembled aircraft and automobile engines are transported to testing stands, where after proper warm-up, their smoothness and uniformity of operation, performance, and fuel consumption are examined. They also undergo tests on the brake dynamometer and rear axles of automobiles for noiselessness and precision of operation. Aircraft engines are tested according to precisely established regulations, under the supervision of both military inspection authorities and factory inspectors, in line with the customer’s motor order. The brakes of both automobile and aircraft engines are modern and well-equipped with all necessary and auxiliary devices, measuring instruments, and more.

All new types of aircraft engines are subjected to long-term tests on the brakes, carried out in accordance with both international regulations and specific rigorous guidelines of the Ministry of National Defense (MNO), with continuous operation lasting 50, 100, or more hours. These extended tests, routine acceptance tests, and close collaboration with leading military and civilian pilots contribute valuable insights and experiences to the factory, which become invaluable guides for future designs.

The brake testing of aircraft engines falls under a dedicated independent department, forming a separate division within the factory. This department exercises the strictest supervision over all tests, ensuring that only thoroughly tested and operationally reliable machines reach the hands of customers.

The attached images depict the most sought-after designs of personal automobiles, featuring both open and closed bodies. The Walter company currently produces two types of personal vehicles: a six-cylinder (6 B) with a 3-liter capacity and a four-cylinder (4 B). Both of these types share the same bore and stroke, i.e., 75×108 mm. We had the opportunity to test drive the new Walter six-cylinder, which can be confidently said to compete favorably with the top-notch foreign products, boasting exceptional performance, smooth operation, impeccable suspension, and an appealing exterior.

From commercial vehicles, the Walter company manufactures the versatile two-ton PN model, the versatile attributes of which are partly evident from the illustration. Interestingly, the Ministry of Posts has recently acquired nearly a hundred chassis of this type for its postal buses.

The Walter factory has its own body shop, producing all kinds of special, luxury, and serial bodies, which are well known from Prague’s automotive exhibitions, always capturing the attention of all visitors.

Within the factory, we also find an extensive repair department exclusively handling vehicles of their own production. This department is also equipped as comprehensively as possible to ensure efficient, swift, and cost-effective work.

Leaving the Walter company’s factory, we are satisfied to have had the opportunity to thoroughly acquaint ourselves with this outstanding enterprise that stands at the forefront of its time. We present to our readers these interesting notes and images that document the high level of quality of Walter automobiles and aircraft engines. It’s not an exaggeration to apply the company’s motto to them: “One manufacturer – one quality.”

Aircraft engines “Walter” 60 hp and 120 hp on test brakes. “Walter-Jupiter” engine 420 hp on brake in operation.

“Walter” aircraft engines and their application in the Czechoslovak Republic are the subjects of discussion.

A moment of conversation with Chief Captain Field Pilot Josef Hermanský:

Chief Captain J. Hermanský shared insights about the training of military pilots and his inaugural compass flight from Prague to Olomouc.

Josef Heřmanský was a Czech fighter pilot and commander. Image: 1928.

“Every military pilot who has passed preliminary aviation schools and courses must join an aviation regiment after their completion, where they are assigned to a unit within the regiment called ‘aviators.’ Here, the challenging part of aviation work begins, and through constant training, they become field pilots.

Although they have a whole year for this, the conditions to attain this title are appropriately demanding, offering plenty of challenges. Various factors are at play, some of which may delay rapid completion, often stretching the duration to almost a full year, and conditions are barely met in time.

Weather is the most decisive factor, followed by the unit’s schedule and, ultimately, the aircraft itself, where the engine is of primary importance. It is the heart of the aircraft. Once it stops, the task remains unfinished and must be redone.”

But when everything goes well as desired, the pilot will carry away several beautiful memories that are unforgettable. I also recall one such qualifying flight, for which there was so much beauty, charm, and tantalizing allure that it left such a strong impression that I gladly revisit it even today, not only in memories but also in reality whenever the opportunity arises.

On a lovely spring day, when nature had adorned itself with a new robe of vibrant green, full of strength and life, I received permission to undertake a qualifying compass flight from Prague to Olomouc and back to Prague, maintaining an altitude of at least 4000 meters. I was provided with an A-ll aircraft equipped with a 240 HP Walter engine.

After all the preparations for the flight were completed, I climbed into the cockpit after fulfilling the necessary formalities. I started the engine, conducted a brief ground test, set the compass to the initial course, and taxied to the runway. After releasing the brakes using the starter, I took off from the airstrip and began to gain altitude. Once I reached the designated 4000 meters, as indicated by two altimeters, I set the course direction and followed the route. During the flight, I had to change the course multiple times as prescribed.

To verify if I was flying correctly according to the compass, I compared my map with the terrain below. All the irregularities of the land disappeared entirely, making it seem as if a vast map was spread beneath me in the depths below, with its miniature replica held in my hand at altitude.

Still above Prague, as I looked around, I could clearly see Kolín, Litoměřice, Beroun, and Benešov. Beyond them, the land merged with the edge of the sky in the distance. Everything was going smoothly until Pardubice, where the landscape below me began to be covered by continuous clouds. As far as I could look ahead from this height, there was nothing to be seen except a beautiful, sometimes gently undulating, silver expanse bathed in sunlight. I pondered whether I should venture into this vast unknown and seemingly endless cloud cover. I hesitated whether to continue flying, wanting to turn back, yet the temptation to experience something I had never encountered before was strong.

I questioned myself, should I venture into this immense unknown, into the seemingly endless expanse of clouds? I hesitated, considering whether I should continue or turn back. I was intrigued by the idea of flying above closed clouds, all by myself. Something kept whispering to me, “Give it a try!” And since my Walter engine was running so smoothly and reliably, assuring me of a certain outcome and fulfilling the conditions, I succumbed to this temptation. I decided to fly further. And indeed, Walter did not disappoint. In those moments, I experienced some of the most beautiful moments of my life.

As far as the eye could see, it was all white — an endless sea of clouds — merging with the deep blue sky in the distance. Above, the sky was blue, and the sun was shining brilliantly. All around me was nothingness, and I was alone in this vast expanse with my aircraft. There was nothing for the eye to rest upon. I was the master of this unknown realm, unseen by anyone, and seeing no one myself.

Solitude, in which the senses work calmly and evenly, giving rise to various emotions and thoughts.

Sacredness, interrupted only by the whisper of my Walter engine. I felt so content that I recalled my childhood and school-day visions of the sky. I completely forgot about the earthly troubles that I couldn’t see from up there and that I had detached myself from. I forgot about everything. Enthralled by what I saw and felt, I exclaimed and shouted, “You’re the master of everything you see.”

The Walter engine continued to run smoothly, and it seemed to me that it was getting better and better as I went further.

In this state of mind, I delighted in the experience for about an hour and a half, during which I roughly calculated that I would be over the prosperous Haná region, specifically Olomouc. Torn from this ethereal sanctuary, I looked around, and in the distance to the right, I spotted a larger gap in the white expanse. I reduced the throttle and descended straight towards it. I slipped through the layer of clouds, about 400 meters thick, with a base around 800 meters above the ground.

Beneath the clouds, I surveyed the land, comparing the map to the terrain, and then I saw a town. Recognizing the church on St. Kopecek Hill, I identified it as Olomouc, my destination. I smoothly landed at the airport and proceeded to thoroughly check both the aircraft and the engine.

After about two hours of downtime, once everything was complete, I prepared for the return flight. This time, the gods were not as favorable as they were during the journey to Olomouc. I had to experience the challenges of flying, even the less enticing aspects. Nevertheless, it was no less exhilarating than the first flight.

The meteorological report from Prague indicated fair weather, but from the Czech-Moravian Highlands, through which I was to fly to Nemecký Brod, there was a slight rain. In Olomouc, it was overcast. Not the most inviting forecast for a novice pilot. However, there was no other choice but to decide on the return flight. According to the forecast, the weather was expected to deteriorate, potentially resulting in spending days stranded on a foreign airfield.

I took off and steered under the clouds towards Nemecký Brod. I maintained an altitude of 700 meters. As I flew towards the Czech-Moravian Highlands, I noticed that the terrain was getting closer, and in the Highlands themselves, the peaks of hills sometimes merged with the clouds. I had to find valleys to progress forward. Occasionally, I flew through patches of rain, until finally, I reached Nemecký Brod. From there, I changed my course to Prague via Kolín, following the Reich road. The terrain started to recede again, clouds were breaking apart, and at places, they were becoming thinner. Around Habr and Čáslav, I encountered only scattered clouds of various sizes. In comparison to my first flight, the weather in Bohemia had significantly worsened.

Inspired by the first flight, I began to climb again towards 4000 meters. However, it wasn’t as hermetically sealed as before below me. I could still see the ground, although it was partially covered by individual clouds of varying sizes. It was beautiful as well, but it couldn’t compare to the first flight. Without realizing it, I was back in Prague again. I descended and landed at the airfield.

After landing, I gave my aircraft a gentle pat and thanked “Walter.”

The remarkable figure whose name became inseparable not just from his creations but also from the Jinonic district, left this world quietly on January 15, 1950, with minimal public attention.

As time marches on, however, we find ourselves captivated by the extraordinary global legacy molded by the innovative genius of the Czech visionary, Josef Walter.

It is through the lens of history, that we witness the profound impact he has left on the world, a testament to Czech ingenuity and an unwavering commitment to advancement. From the humble origins of a machine fitter’s apprenticeship to the pioneering days of aviation, Josef Walter’s journey resonates deeply, urging us to embrace the unexplored, surpass limitations, and etch our narratives onto the fabric of time.

As we contemplate the remarkable tale of Josef Walter, let us also acknowledge the resounding influence of one Czech individual’s fervor in shaping the world for present and future generations.

Did you enjoy learning about this today?

Click here for some more historic photos of the factory.

Click here to learn more about the Walter Czech engine in airplanes today.

Watch Martin, a lovely Czech man explain the engine in an older Zlin airplane below:

Learn more about the new Waltrovka here.

I’d love to read your comments!

We tirelessly gather and curate valuable information that could take you hours, days, or even months to find elsewhere. Our mission is to simplify your access to the best of our heritage. If you appreciate our efforts, please consider making a donation to support the operational costs of this site.

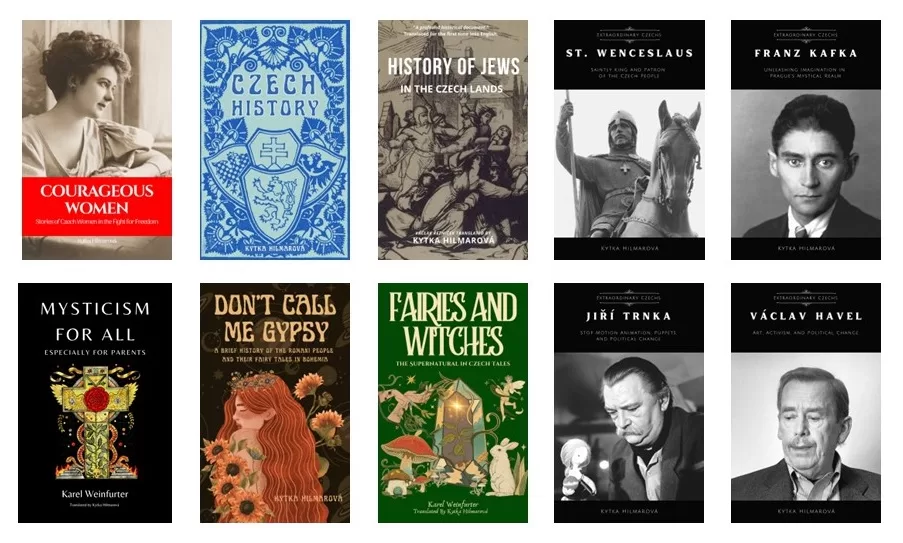

You can also send cash, checks, money orders, or support by buying Kytka’s books.

Your contribution sustains us and allows us to continue sharing our rich cultural heritage.

Remember, your donations are our lifeline.

If you haven’t already, subscribe to TresBohemes.com below to receive our newsletter directly in your inbox and never miss out.